C260 CodeJet Carton Printer

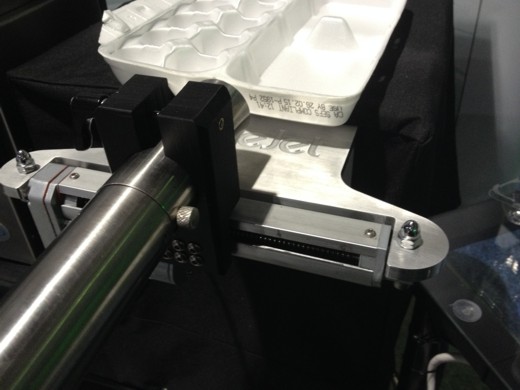

C260 Printhead with Traversing System

CA-SEFS Compliant can be printed by the C260 printer on the side of an egg carton in 1/4" tall characters with another line of variable data printed beneath it.

12, 18 or 24 Pack cartons with varying print areas are easily handled with the traversing system. The print position for a particular carton is stored in the database with the job and uploaded to the printer simultaneously.

The C260 CodeJet printer can operate in 3 modes on an egg packaging line:

1) In conjunction with a small traversing system, the C260 prints carton code data after the denester while the carton is still open and stationary. Regardless of whether the carton is closed or not, the cartons are correctly printed and no ink is printed on the eggs, eliminating rework.

2) The prithead can be mounted to print on open cartons while they are in motion.

3) The C260 printhead can be mounted after the carton closer either in a stationary mode (carton moving) or with the traversing system (carton stationary).

The C260 printer and interface software moves egg carton coding from contact coding into the world of digital printing. Best-before dates and production dates are easily created and automatically updated by the printer, even following an overnight shut down. Once a message has been downloaded the printer can operate by itself in offline mode. Combined with Independent Ink Inc. specifically designed network software, inks and low cost of ownership, production throughput is greatly extended through fast changeovers and consistent print quality.

INNOVATION

The C260 gives the user a system capable of quickly adjusting to various printing environments and substrates. The C260 offers greater flexibility in pre-selecting print settings, permitting the user greater control over print quality and cost. The software allows the user to select from a database of jobs and change jobs,flock codes, offset days on the fly, see real time print data and counts for each individual printer and make fine adjustments to the print environment settings in order to ensure the highest print quality while also managing the cost per print.

SOFTWARE

The MS Windows-based software provided with the system is extremely versatile; it can be configured to print a variety of data including Sell By Date, Manufacturing Date, Plant Number, Flock Code, Time and Text of various sizes and fonts. The user friendly interface and software enables the user to design and print different types of information and to control the print image while having a real time picture of the production environment for up to 20 printers.

NETWORKING

Multiple, up to 20 C260 printers can be connected over Ethernet to a single message control PC. The Production Mode software allows message download to each print head and displays the current message being printed, days offset and print count. The software uploads jobs from a job database and can download production data on a daily basis for analysis. To learn more about our industrial printers, please contact us.

There are no products matching the selection.